Have you ever tried to track a highly valuable, custom-built component—like a specialized turbine blade, a flatbed load of essential pipe, or any type of critical infrastructure—using the same basic system you use for an Amazon package?

If you manage Project-Based Logistics, you know exactly how that feels.

I. Why Your Current "Tracking" System Is Failing Your Project Timelines

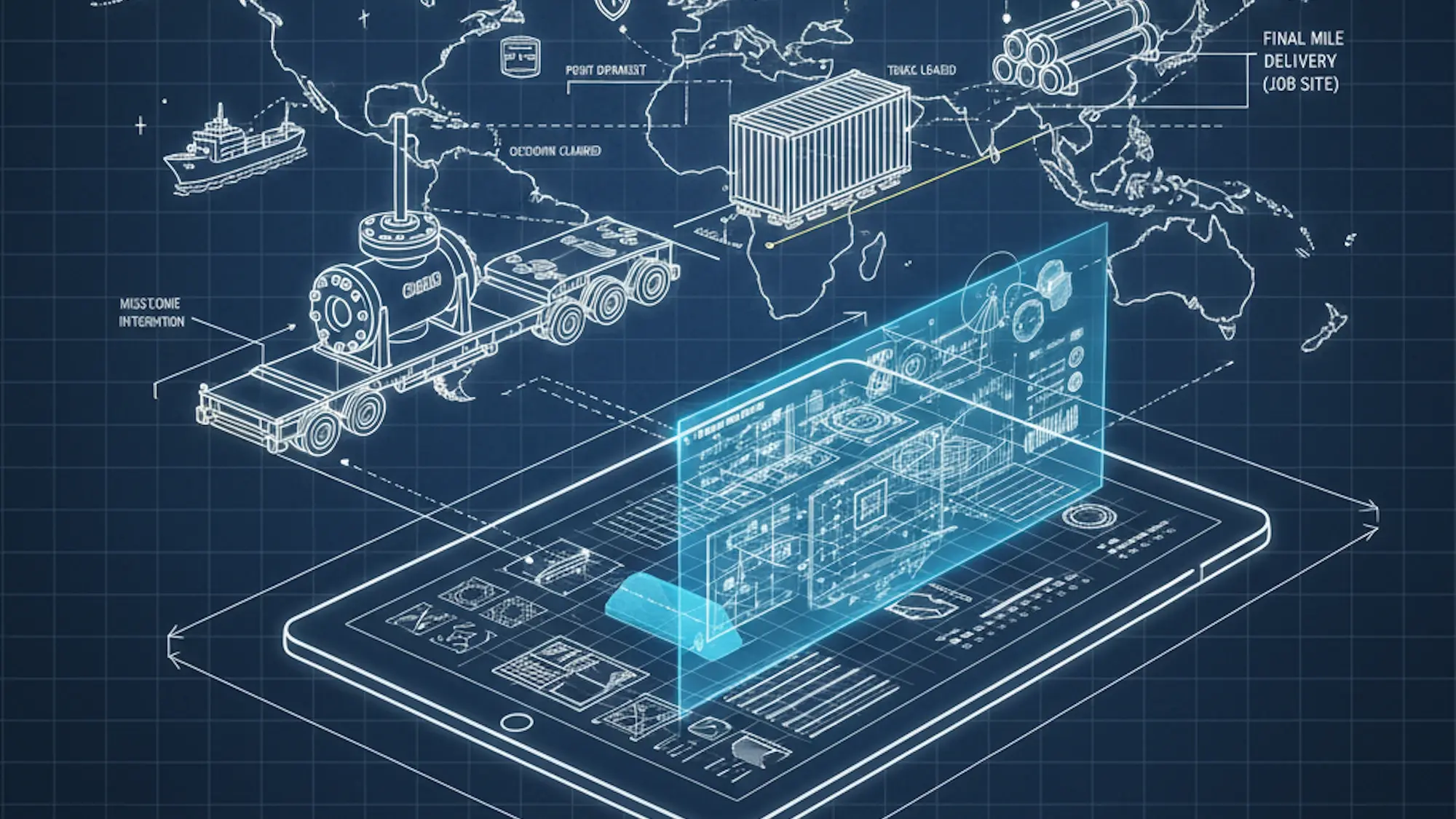

The current system gives you what we call the "simple tracking" illusion. You see a little GPS dot moving on a map, and the status reads "In Transit." That's fine for a regular shipment. But when you're dealing with specialized freight—the kind of cargo where delays can cost millions in project penalties—a simple dot with no context or solid information is useless.

The truth is that you need full visibility into every step of your shipment to keep your project on time and on budget.

This article explains why basic tracking often fails and shows how real, integrated visibility—from the moment you place a PO to final delivery—gives your operation a clear advantage. With full transparency, you reduce risk and always know where your shipment stands.

II. The Visibility Gap: When Important Shipments Go Missing

Why is managing project logistics so different? Because a project shipment journey is a complicated relay race, not a simple straight line.

The journey for a custom-manufactured valve or an OOG (Out-of-Gauge) piece of equipment often involves multiple handoffs, mode changes, and regulatory checks, where tracking often gets lost. These are your visibility gaps:

-

Origin Hand-Off: The moment the item leaves the manufacturer and is handed to a local freight forwarder. Is it truly ready-to-ship, or just packaged?

-

Mode Changes: When shipments switch from ocean or air to heavy haul or standard ruck transport, the different systems don't share tracking data, creating information gaps.

-

The Regulatory Hurdle: Customs clearance, border crossings, and, most importantly, getting the oversize/overweight (OOG) permits. A single customs hold-up or a rejected permit application can stop an entire multi-million-dollar project.

The financial risk is enormous. In North America, one report suggests that 98% of construction projects face delays, stretching the duration of work by an average of 37%.

For large-scale projects, the losses from any delays can quickly grow, costing companies an estimated $1.5 million per day in some sectors. This is what happens when you depend on unclear "In Transit" updates instead of getting the details you need..

Project managers waste time piecing together shipment info, calling different carriers, and making last-minute changes to project schedules—all with incomplete data. This reactive approach creates bottlenecks and increases project risk. For more on these issues, explore our discussions on specialized freight management and achieving cost and visibility goals.

III. Defining Real Project Visibility: Track Milestones, Not Dots

So, if simple tracking fails, what does true end-to-end visibility look like for specialized freight?

It’s about replacing generic updates with specific, project-critical milestone tracking.

For high-value project-based shipments, true visibility means getting confirmation on five specific events that impact your schedule:

1. The Pickup

You need confirmation that your shipment has been "Picked Up" at the supplier's dock. This is a hard logistical event, not a vague promise of a ready-to-ship date.

2. The Regulations

Are Customs clearance and OOG permits complete and valid? Did you get the "Customs Cleared" update? Having this answer upfront stops a truck from driving hundreds of miles, only to get held up at a border or port and throw off your schedule.

3. The Mode Transitions

When the shipment moves from sea to land, the system must confirm the "Loaded on Truck" status, including the specific truck and driver ID. This makes sure that you're seamlessly keeping updated on all the data.

4. Scheduled Delivery Windows

You don't just need a hard delivery date (though it helps); you need a confirmed, time-bound delivery window (e.g., "Arriving 14:00-16:00 on Tuesday"). This lets you to schedule your high-cost construction or maintenance crews specifically for that time, avoiding the expense of having your crews stand around with nothing to do.

5. On-Site Confirmation

The final, crucial milestone: "Delivery Offloaded and Confirmed on Site." This closes the loop and allows your project team to move immediately to the installation phase.

The biggest improvement comes from connecting your planning systems with your logistics technology. When milestone updates flow straight from your logistics platform into your client’s project management or ERP, you stop scrambling for information and start solving problems before they happen.

IV. Bridging the Gaps With Technology

The core problem is fragmented data. The key is using technology to bring all your logistics data together in one place, which is what sets true specialized freight management apart..

Unifying the Data

Getting this level of supply chain clarity takes the right technology. It’s more than tracking a GPS dot—it’s about connecting everyone on one platform.

API/EDI Integration: The system automatically gathers shipment data from all parties—manufacturers, ocean carriers, customs brokers, and trucking companies—so you have one reliable source for your supply chain.

Standardization: Data from different carriers, which often use different terms for the same events, gets cleaned up and unified into simple milestones that make sense for your project plan.

Proactive Alerts: Immediate Warnings to Prevent Delays

The real value of advanced logistics technology is simple: it warns you about shipment problems before they turn into costly delays. A smart platform continuously tracks each key event, automatically checking if things are running late.

For example, if a flatbed truck is four hours behind, the system instantly alerts your project manager. With this information, you can quickly switch to air freight for an urgent part and keep your schedule on track—avoiding expensive delays and shutdowns. This is both risk mitigation and risk reduction at play.

This proactive approach is essential for complex projects where every hour matters. As covered in our specialized freight management analysis, detailed and timely milestone tracking protects your budget and ensures projects finish on time.

V. The Decision-Making Advantage

Getting this integrated, proactive visibility takes your business past simple freight brokerage. It shifts the discussion from if a delay will happen to how fast you can come up with a solution.

When you use a platform with clear, unified tracking for your project shipments, you get two big benefits:

1. Better Risk Control: Instead of reacting to problems, you get reliable data that helps you prevent costly project delays.

2. More Team Efficiency: Your staff spends less time chasing shipment updates and more time focusing on running the project.

To reach this level of reliable, proactive management, you need a logistics partner who connects every step of your complex shipments into one seamless process.

VI. The Custmodal Difference: True Control Over Your Project Shipments

For project shipments, basic tracking isn't enough—missing details can mean missed deadlines and major costs. If data is scattered or tracked by hand, your risk grows. You need a partner with systems built to manage every step of complex specialized freight, start to finish.

This is where Customodal steps in.

Managing project logistics takes more than just picking a carrier—you need a system that connects and tracks data from every carrier, forwarder, and customs checkpoint. Customodal brings all this information together by linking directly with each partner, so you always know where your shipment is at each stage.

Our system keeps an eye on every shipment and alerts you right away when something might cause a delay, like a late truck. This way, you can fix small problems before they become big ones, helping you save money and keep your project on time.

When a high-value, unique component is critical to your success, you need the highest level of control and predictability. That control is found in true visibility.