What is the single most expensive asset on your job site? If you answered with the price tag of your largest excavator or mining truck—say, a $5 million machine—you'd be technically correct. But if you answered with the time that the asset spends sitting still, you'd be hitting the financial bullseye.

For projects that rely on heavy equipment—whether it's heavy construction/mining equipment—unexpected downtime isn’t just a setback; it can quickly become a serious problem. The costs add up fast, including lost productivity, contract delays, and idled crews.

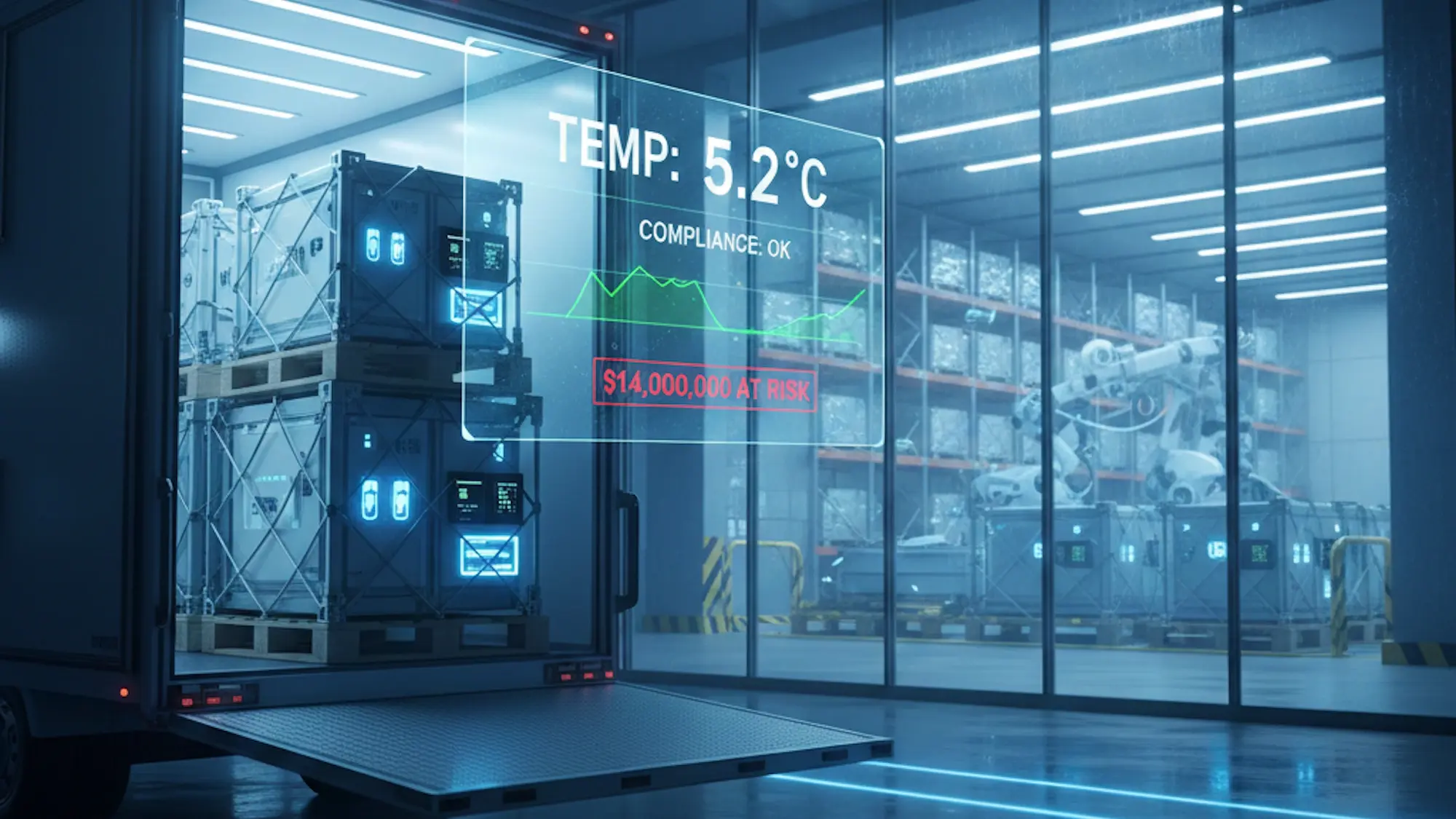

In today's industrial world, just one hour of downtime can mean losses of $125,000 to more than $2 million, depending on the operation's size, with heavy industry seeing these costs increase year after year.

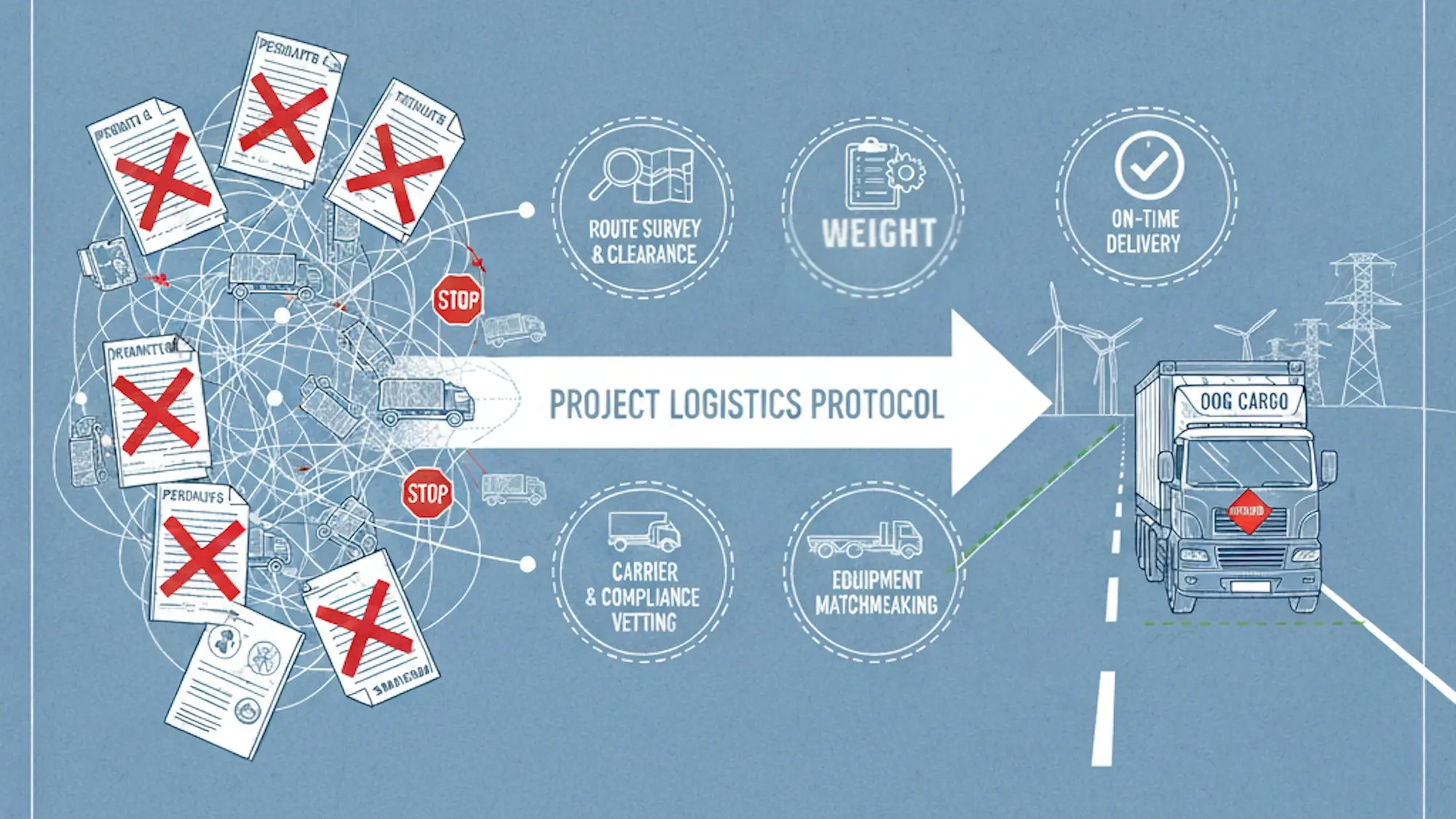

Getting your revenue back on track starts with fast, reliable urgent parts delivery. That's the heart of Specialized Freight Management (SFM). At Customodal, we treat a downed bulldozer as seriously as an "Aircraft On Ground" (AOG) event—relying on project-based logistics to get your heavy equipment up and running quickly and precisely.

This isn't about ordinary shipping—we're talking about the logistics strategies that keep your most important equipment running and your projects on track.

1. The Downtime Disaster: Why Speed is Cheaper Than Waiting

It's essential to set aside budget for "hot-shot" logistics, even if the upfront expense seems high, because the cost of waiting is always higher.

When a key part fails—whether it's an engine block, hydraulic pump, or gear set—your equipment stops working and quickly becomes a $5 million loss. Every hour it's down means lost revenue and more project delays.

-

The Financial Pain: If your project incurs $15,000 in losses for every hour of downtime, waiting two days for a standard freight part results in $ 30,000 in lost revenue. Spending an extra $5,000 to have the part flown in—cutting 40 hours of downtime—isn't just an expense; it's a strategic investment. It's a smart move that saves $595,000 during a critical moment.

-

The Ripple Effect: Downtime cascades. It halts downstream work, idles crews, forces overtime to catch up, and can damage long-term client relationships. As we've noted before, achieving accurate cost predictability and visibility of specialized freight and critical parts is essential to minimizing these hidden costs.

For equipment owners, what matters most is keeping machines working. Choosing the fastest and most reliable parts logistics isn't just smart—it's the best way to protect your bottom line.

2. Global to Local: The Multi-Modal Relay

You've located the critical part to get your operation back up and running—but here's the following challenge: it's manufactured in Germany. It must be transported to a remote, high-altitude mine in Chile. How do you move a two-ton part across oceans and continents to a spot that may not even have paved roads?

This is where Specialized Freight Management becomes essential. Delivering an urgent equipment part is always a well-orchestrated, multi-step process—not a quick, single-mode shipment.

The Complexity of Global Reach

-

Air Freight to the Hub: The high-value component must be safely secured and quickly shipped by air from the manufacturing site to the nearest main international gateway, often requiring special handling due to its size, weight, and importance.

-

Customs and Compliance: General providers often encounter difficulties at customs. If a key part gets stuck there, your operations remain idle. Specialized Freight Management involves having documentation ready, a thorough understanding of customs rules—including duties, taxes, and permits—and carefully following transport requirements to prevent costly border delays.

-

The Final Mile Hot-Shot: Once the part arrives, the next critical step is getting it quickly to the final, often remote, job site. This means using dedicated ground transportation—hot-shot or expedited truck service. Unlike standard trucks, these specialized vehicles and drivers are ready to go at a moment's notice, heading straight to the destination even if it's off-road. The goal is nonstop, direct delivery for maximum speed and security.

When you manage logistics for heavy equipment parts, you're getting fast, reliable global coordination—not just a basic shipment.

3. Speed vs. Cost: Finding the Balance

When an operations manager requests "expedited shipping," air freight is usually the first option that comes to mind. But in Specialized Freight Management, air is just one part of the solution. The quickest route often isn't the most obvious.

The Fastest Total Route

Effective global parts logistics involves calculating Total Transit Time (TTT) and selecting the optimal combination of transport options that aligns with the client's budget.

-

Dedicated Ground Advantage: Often, the domestic leg causes the most delays. Using a dedicated truck to take a critical part straight from the manufacturer to the airport—skipping crowded warehouses or cargo terminals—can save several hours or even a whole day. This smart move, utilizing specialized trucking, often delivers better results than relying solely on the fastest air service.

-

The Power of Proactive Visibility: In critical moments, not knowing is the biggest obstacle. The right logistics partner provides clear, end-to-end visibility—so site leaders can schedule crews and cranes to coincide with the arrival of a crucial part. Proactive updates help minimize downtime, letting installation start right away, which saves costs and keeps the project on track.

When you balance speed, reliability, and thoughtful logistics planning, shipping becomes more than just a service—it turns into a key way to boost asset productivity.

4. Reverse Logistics: The Hidden Uptime Strategy

Once the new part is installed, the immediate problem is solved—but logistics don't end there. Many equipment owners, especially those with high-value assets, often overlook the critical step of arranging reverse logistics for the returned part, commonly referred to as the "core."

Protecting Your Financial Margin

A key part of heavy equipment aftermarket operations is returning the failed part—called the "core"—to the manufacturer for repair or refurbishment.

-

Warranty and Core Credit: Failing to return the core exactly as the manufacturer requires—often within a tight deadline—can mean losing valuable warranty credits. This can cost tens of thousands of dollars, wiping out the benefits of fast parts delivery.

-

The Coordinated Pickup: A specialized logistics provider handles both outbound delivery and core return as a single, seamless process. The exact vehicle that delivers the replacement part is ready to collect and transport the core back to the manufacturer's facility immediately. This approach requires careful crating, clear documentation, and strict compliance from pickup to final delivery—protecting the core's integrity and value at every step.

In the heavy equipment aftermarket, effectively managing core returns is crucial to achieving long-term profitability. Here, logistics isn't just moving freight—it's a meaningful way to protect your financial assets.

The Specialized Difference: Going Beyond Standard Freight

The mission is always the same: uptime guaranteed. Most freight providers are set up for high volume and routine shipments—not for handling the urgent, complex needs of moving high-value, heavy parts across continents.

Specialized Freight Management is the difference between an acceptable delay and a catastrophic one. It requires:

- Extreme Urgency Focus: Treating every critical part as an AOG mission.

- Global Multi-Modal Expertise: The ability to orchestrate air, dedicated ground, and customs processes seamlessly.

- End-to-End Control: Providing detailed visibility and managing the often-forgotten reverse logistics of the core.

When the financial risk is this high, your logistics partner needs to act as both an expert advisor and a valid extension of your team. They must see that the five-ton part on their truck isn't just cargo—it's essential to your revenue.

Customodal is here to help. We're experts at moving high-value, urgent, and complex freight, providing the specialized logistics needed to keep your heavy equipment operational. We handle the logistics so you can focus on your projects—not tracking shipments.

Don't let freight delays threaten your assets or profits—Trust Customodal to keep your equipment, and your business, moving.