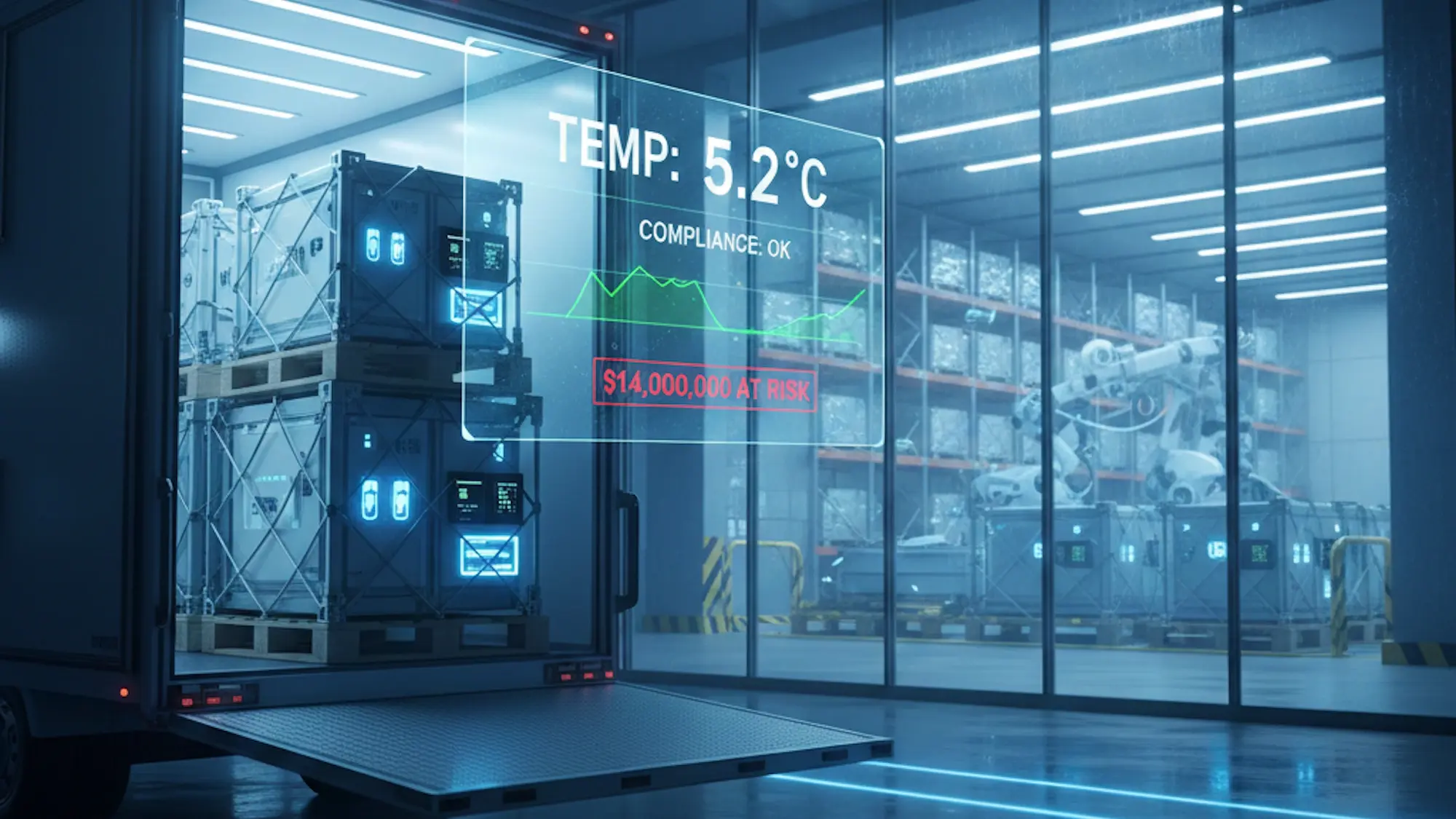

Imagine this scenario: You've spent years and millions on research and development. Your advanced medical device or specialized pharmaceutical product is finally ready for its market launch. The quality controls in the lab were perfect. But then, somewhere between your facility and the end-user, a small, preventable error occurs: temperature fluctuation.

Suddenly, your multi-million dollar shipment is compromised. It's not just a late delivery; it's a complete failure of product integrity that triggers a cascade of financial and regulatory fallout.

This is the "$14 million question" facing C-suite executives and supply chain directors today. It's the question of whether your logistics approach is a reliable protective measure or the single greatest threat to your product revenue. A 2023 report cited that,

Supply chain issues (including temperature excursions) resulted in a loss of over $14 billion in pharmaceutical revenue globally

For your company, the cost of one single failed shipment is measured in terms of months of delay, loss of critical inventory, and the complete erosion of market trust.

The stakes are immense. In this high-value, high-risk environment, compliance in temperature-controlled logistics isn't a formality—it's the fundamental shield that protects your revenue pipeline, market access, and reputation.

The Anatomy of Specialized Cold Chain Logistics

When we talk about cold chain logistics, we're not just referring to a refrigerated truck carrying produce. This is a highly precise, unbroken, and documented process essential for transporting sensitive, high-value freight.

Think of an advanced MRI component or a highly engineered pharmaceutical ingredient. These components represent not just a high price tag, but years of R&D and millions in projected sales. If the temperature deviates even slightly outside of a defined, scientifically validated range, the entire part or batch is rendered unusable.

Specialized freight management (SFM) for cold chain cargo demands a different kind of expertise. It requires an integrated understanding of the cargo's unique requirements and the logistics pathway.

The Critical Chain of Custody

For these sensitive goods, temperature control must be continuous and verified across every single transition point:

-

Manufacturing & Packaging: Using validated, thermal packaging.

-

Transport: Utilizing qualified carriers and temperature-controlled equipment.

-

Storage: Ensuring compliant warehousing and staging areas.

-

Final Delivery: Maintaining the cold chain until the product is safely in the hands of the end-user.

In this environment, a temperature log is as important as the bill of lading.

The Unforgiving Wall: GxP and FDA Compliance

For high-value freight, especially in the life sciences, every logistical decision is ultimately a compliance decision. The entire chain must adhere to Good Practices (GxP), encompassing Good Distribution Practices (GDP) and Good Manufacturing Practices (GMP).

These regulatory standards exist to ensure that products are safe, maintain quality, and are traceable. For companies transporting critical devices and pharmaceuticals, compliance isn't optional—it is the gatekeeper to market entry and sustained operation. The failure to comply can lead to severe consequences, including product seizures, mandated recalls, and heavy financial penalties. The FDA, for instance, issued over 500 warning letters related to GMP in a recent year, with many stemming from failures in critical areas, such as documentation and quality control.

Where Logistics Fails the Audit

Many standard logistics providers falter because they lack the necessary rigor for complex compliance. The biggest failures often happen in three critical areas that directly affect your revenue:

-

Validation: A Specialized Freight Management (SFM) partner must scientifically validate the packaging, routes, and equipment under worst-case external conditions. Standard carriers often rely on general assumptions, which can be deadly when your cargo is sensitive.

-

Documentation & Audit Trails: The GxP environment demands comprehensive, uneditable, time-stamped records showing continuous temperature mapping from origin to destination. If your partner can't provide a meticulous data integrity report instantly, you have a compliance gap.

-

Excursion Protocols: What happens the moment a temperature breach occurs? If your partner doesn't have immediate, documented, and practiced Standard Operating Procedures (SOPs) for responding to and reporting a temperature excursion, the entire shipment is potentially compromised.

The cost of non-compliance is not just a fine; it's the destruction of valuable, critical product, leading directly back to the catastrophic revenue loss embodied in the $14 billion question.

The Real-World Risk: From Minor Fluctuation to Major Loss

Let's look at a concrete example that illustrates the danger of treating cold chain logistics and compliance as just another delivery.

A highly engineered electronic component, crucial for a piece of heavy medical imaging machinery, must be maintained between 18°C and 22°C. This component is worth $2.8 million and is scheduled for a Just-In-Time delivery to a hospital installation site.

A standard logistics provider, focused purely on speed, uses a basic passive refrigerated container. During transit, an unexpected weather delay in a warmer climate holds the cargo on the tarmac for two hours longer than anticipated. The internal temperature of the container spikes to 26°C for 45 minutes.

Though the component might seem fine, its internal validation dictates a strict operating temperature range. Because the carrier was not qualified and the packaging was not validated for that specific high-risk lane, the product is technically compromised. According to GxP rules, the entire shipment must be quarantined, extensively tested, or, more commonly, destroyed.

The result? The entire $2.8 million shipment is a total loss. But the damage doesn't stop there: the hospital installation is halted, causing revenue downtime for your customer, and your reputation as a reliable supplier is critically damaged. This scenario illustrates why a project-based logistics mindset, rather than simple transactional shipping, is essential for high-value components.

You cannot afford to manage specialized cold chain reactively. You need a partner that uses risk assessment, thermal mapping, and pre-vetted, qualified carriers to prevent the alarm in the first place, ensuring your product uptime and maintaining your revenue flow.

Strategic Steps for Mitigating Cold Chain Risk

Moving from risk exposure to revenue protection means changing your approach and changing your partner. For critical, temperature-sensitive freight, logistics can never be transactional.

Moving Beyond the Standard Broker

When engaging with a potential partner for your specialized freight needs, you must ask the challenging questions that move beyond simple rate quotes. As we've stated before, only a true Specialized Freight Management (SFM) partner can provide the necessary rigor.

Here are the non-negotiable questions to ask your logistics provider to ensure true cold chain logistics and compliance:

-

"How do you demonstrate thermal packaging validation for my specific component and lane?" (The answer must involve scientific data, not a general assurance.)

-

"What is your GxP-compliant audit trail for a temperature excursion?" (They must have a detailed, immediate, and documented reporting process.)

-

"Do you have a dedicated, specialized SOP for my high-value freight, and is it shared with all handlers?" (Generic processes will not suffice for critical inventory.)

This level of dedication is what separates a logistics provider that views your shipment as "freight" from one that understands it as "critical, non-negotiable revenue."

The Technology Imperative

Today's specialized freight management relies heavily on technology. To deliver on the promise of compliance, a partner must integrate:

-

Advanced IoT Tracking: Real-time data loggers that transmit temperature and humidity data continuously.

-

Predictive Analytics: Using historical route data, weather patterns, and traffic to anticipate risks before they compromise the product.

-

Digital Audit Trails: Providing instant, immutable, and verifiable documentation for every regulatory audit.

The Value of Specialized Expertise

The "$14 Million Question" isn't about if a compliance failure will happen; it's about when and if your logistics partner is equipped to prevent it. Protecting your revenue pipeline—and your reputation—depends entirely on unbroken regulatory and temperature compliance in your specialized cold chain.

When the stakes involve high-value, sensitive components and the unforgiving standards of GxP and the FDA, a standard freight broker simply cannot provide the necessary level of validation, documentation, and compliance rigor. This demanding environment requires a partner whose primary focus is on Specialized Freight Management for critical components.

At Customodal, we don’t just move freight; we manage critical projects with an intense focus on minimizing your risk and guaranteeing the integrity of your high-value components. Our specialized process is designed to meet and exceed the toughest compliance standards, transforming the cold chain from your greatest vulnerability into a reliable competitive advantage.

Ready to stop worrying about the $14 Million Question and start securing your critical shipments and revenue?

Contact Customodal today to discuss a validated, compliance-first approach to your specialized cold chain logistics.