Are you certain your complex, dangerous goods compliance strategy is up-to-date, or are you playing regulatory roulette with your high-value assets?

The intersection of heavy haul (oversized storage units, project cargo) and the rapidly changing Dangerous Goods (DG) regulatory landscape is the industry's single largest risk factor right now. It's no longer enough to simply ship a box; you must now expertly manage risk from manufacturing to final installation.

The global shift to electrification—from electric vehicles (EVs) to utility-scale energy storage—means lithium-ion battery shipments are ubiquitous. This rapid adoption has made them the most frequently cited violation in logistics. This is a high-stakes problem. Why? Because non-compliance can be catastrophic. The Federal Aviation Administration (FAA) and Department of Transportation (DOT) have stepped up enforcement;

Citing companies that faced fines exceeding $300,000 for improperly declared, packaged, and mislabeled battery shipments, sometimes resulting in thermal incidents or cargo fires.

This article will move beyond basic checklists to detail the specific regulatory landmines in specialized battery logistics. We will explain why a general logistics provider is simply insufficient and cover the critical questions you must ask a potential partner to de-risk your project's supply chain and protect your uptime.

What are Dangerous Goods (DG)?

Dangerous Goods (DG), also known as Hazardous Materials (HAZMAT), are substances or articles that pose a significant risk to health, safety, property, or the environment during transport. This non-competitive classification is governed by global regulations (UN Model, IATA, IMDG, etc.) to ensure safety across all logistics modes.

Materials are categorized into Nine Hazard Classes based on their primary risk, from Class 1 (Explosives) through Class 8 (Corrosives) to Class 9 (Miscellaneous). Our specific focus, lithium-ion batteries, falls under Class 9.

Every DG item is assigned a unique UN Number and a Proper Shipping Name, along with a Packing Group (I, II, or III) that indicates the degree of danger. Understanding this classification system is the critical first step in dangerous goods compliance, demanding expert handling, packaging, and coordinated transport documentation to mitigate severe regulatory and safety risks.

The Cost of Complacency: Navigating the 2025-2026 Dangerous Goods (DG) Changes

Is my current compliance strategy still valid for 2025 and 2026?

The short answer is likely no. The regulatory environment for batteries—spanning IATA, IMDG, 49 CFR, and PHMSA—is not static; it evolves annually to keep pace with technology and safety demands. What worked last quarter might expose you to risk today.

A general freight forwarder might gloss over these details, but for projects requiring specialized freight management, this is where expertise pays off. Ignoring new regulations can dismantle a project schedule and erode confidence faster than any supply chain delay.

Here are the most critical recent updates that a decision-stage reader must know:

-

Tighter State of Charge (SoC) Restrictions: The mandate for lithium-ion cells and batteries to be shipped at a State of Charge (SoC) not exceeding 30% of their rated capacity is now applying more broadly to batteries packed with or contained in equipment. This technical detail can drastically change your preparation and staging processes.

-

New UN Classifications: Regulators have included new entries for cutting-edge power sources, such as Sodium-ion batteries (UN 3551, UN 3552), and dedicated numbers for battery-powered vehicles (UN 3556, UN 3557). These changes standardize what was previously an ambiguous or complex classification, which helps experts manage the documentation but complicates the process for non-specialists.

How does DG complexity change when the shipment is also oversized?

This is the central challenge in advanced logistics. When Dangerous Goods (DG), like a multi-ton battery storage unit or a large power pack, are also part of a larger project or heavy haul shipment, the complexity multiplies exponentially.

For a battery storage facility, your logistics provider must coordinate hazmat documentation with specialized requirements like route planning, state-by-state permits for oversized loads, and the need for hazmat-certified drivers and escorts. A company that is only a freight broker may effectively manage the DG paperwork but simply cannot manage the specialized, coordinated ground movement of an oversized battery containment unit. This dual-risk factor is precisely why specialized management is essential, as detailed in our discussion on why project-based logistics beats simple permits for Hazmat shipping.

Beyond the Label: The Three Hidden Compliance Landmines

Effective dangerous goods compliance requires expertise that goes far beyond merely sticking the correct hazmat label on a box. It requires managing documentation, internal packaging, and external storage—three areas where most non-specialists fail.

1. The Technical Packaging and Stowage Riddle

What is the biggest physical risk in battery transport?

Incorrect internal packaging is the leading cause of thermal runaway, fire, and explosions. The technical specifications are stringent. For instance, have you secured the mandatory UN 38.3 test summary?

Your partner must have certified experts who understand the highly specific Packing Instruction (PI) details—like PI 965 for loose lithium-ion cells—and the nuances of UN Specification Packaging required for all transport modes. Managing a specialized load is about guaranteeing an environment where the cargo is safe, not just compliant. This is a level of detail that only an uptime partner can provide.

2. Misdeclaration and the Audit Nightmare

How serious is a paperwork error?

Catastrophically serious. It's estimated that roughly:

5% of shipped containers contain undeclared Dangerous Goods, often lithium-ion batteries.

This shocking statistic is a primary driver of major shipping incidents.

Misdeclaration is not just a simple label error; it is a fundamental documentation failure that covers the Shipper's Declaration, the Bill of Lading (BOL), and the required Emergency Response Guidebook. Fines for non-compliance are severe, as noted previously.

Furthermore, in specialized freight management where the stakes are high, the hazmat endorsement (CDL with hazmat endorsement, PHMSA registration) is required for the drivers carrying placarded DG loads. If the carrier isn't properly authorized, the shipment is instantly non-compliant, regardless of how perfect the paperwork may seem.

3. Storage and Staging Compliance

Does compliance end when the truck stops moving?

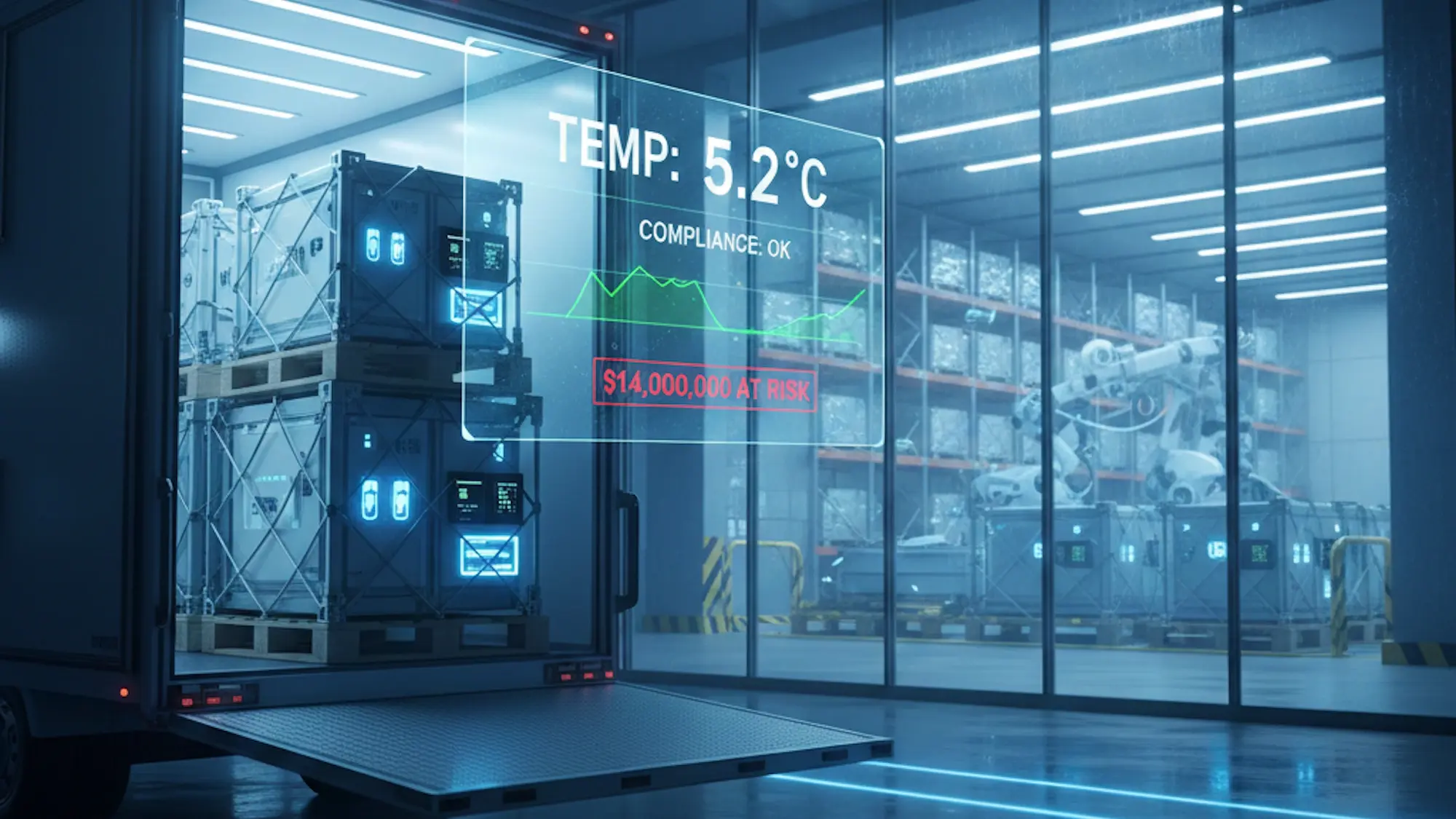

Absolutely not. This is the crucial, often overlooked detail captured in the blog’s title: Battery Storage Logistics. Compliance doesn't end when the truck stops. Large-scale battery projects require dedicated, compliant warehousing and staging areas during a complex installation.

A specialist must ensure adherence to local fire codes, guarantee proper segregation from other dangerous goods (which is a significant complexity in a bustling project staging yard), and provide pre-defined emergency response plans that account for the unique, intense fire hazards of Li-ion’s thermal runaway. This holistic approach is critical for maintaining project timelines and avoiding unnecessary delays, as discussed in the context of scheduled maintenance turnaround logistics.

The Decision-Stage Filter: Evaluating a Specialized Freight Management (SFM) Partner

How do I ensure my logistics partner can handle this level of risk?

At the decision stage, you are no longer comparing quotes; you are evaluating risk mitigation strategies. A general broker focuses on rate; a specialized freight management expert focuses on guaranteed compliance and uptime—the non-negotiable safety of the cargo and the guaranteed timeline of the project.

If your project budget implicitly includes a buffer for potential non-compliance fines that can exceed $39,615 per violation, your partner evaluation process is flawed. You need a partner whose services go far beyond simple transport.

Use these five essential questions as a decision-stage filter for any potential SFM partner:

-

"Can you detail your internal audit process for lithium-ion battery SoC and classification against the 2025/2026 IATA and PHMSA updates?" This tests their current regulatory knowledge and proactive compliance planning.

-

"How does your team coordinate DG paperwork with the heavy haul/oversized permit process, ensuring documentation for both regulatory frameworks is aligned?" This tests for an integrated service that can manage the complexities of both specialized disciplines simultaneously.

-

"Can you provide a specific case example of a project where you handled an oversized/heavy DG shipment that faced regulatory hurdles, and how you ensured final compliance?" This tests for real-world experience and problem-solving capabilities, which is a key part of choosing your uptime partner.

-

"What is your dedicated plan for compliant project staging and storage, including segregation and emergency response for thermal runaway?" This tests their total control over the entire logistics chain, including ground operations.

-

"How often is your team certified (not just trained) in the latest 49 CFR, IATA DGR, and IMDG codes, and can you share an example of a team member's specific DG certification?" This verifies the depth and currency of their in-house expertise.

The Path to Compliance is Through Specialization

The regulatory landscape for dangerous goods compliance, particularly for high-stakes lithium-ion battery logistics, is simply too volatile for a generalist approach. The cost of a non-compliant shipment—in fines, project delays, and long-term reputational damage—dwarfs the cost of working with a true specialist. The path to compliance is clear: You need a partner who views safety and project uptime as non-negotiable.

For sophisticated supply chains where Specialized Freight Management is essential, you need a partner whose DG expertise is integrated directly with their heavy haul and project logistics DNA. We at Custmodal specialize in navigating this complex intersection, ensuring your project's uptime is protected from regulatory risk.

If your project involves complex, regulated cargo, ask the right questions and demand expert answers. The future of your project depends on choosing expertise over simple capacity.